|

Making a Toothpick Dispenser . . .

or . . .

How to turn a log inside-out!

|

|

I've done this project in 2 parts as you can easily create the

dispenser from a single blank of around 45mm diameter and 120mm or so

long if you wish. If you have a larger blank, just skip to

Part B for the actual

making of the dispenser. In Part A, I have tried to show how smaller

sections can be used to optimise some of the beautiful timbers that get

wasted when they are deemed to small to be of use.

|

|

|

|

Part A - Turning a log inside out to create a blank . . .

|

Working with shrubwoods or small trees leaves few options when it comes to

turned objects but this is one way of extending them and showing off the

fantastic colour and grain some of these small timbers hide. Turning

examples like the piece of Purple Bush-pea pictured without some changes

would mean that all you would have to look at would be the rather plain

sapwood with some ugly filler in the huge cracks.

|

|

A

far better option is to split/saw the logs along the heart while green

and seal the ends to stop them cracking while they dry - at this point

they are really only useful for pens and knife scales but that's easy

fixed. If they are around 2" diameter, give the halves about one year to

dry.

For the toothpick dispenser the 'slabs' need to be at least 170mm

long.

|

|

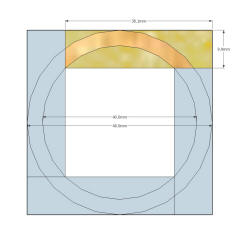

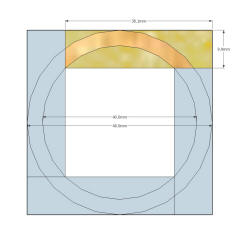

Once dry, slice the slabs to about 12mm thick for this project. A

simple drawing of your cylinders cross section with a square inside and

outside will give you the absolute minimum dimensions you need.

|

|

Mark out the best sections roughly square across the slabs and cut

to length - leave an extra 15 mm or more to turn a dovetail spigot on

one end if you can. In this case I only had a 2 or 3 millimetres to play

with and took a different approach to mounting it on the lathe. The

dispenser cylinder is 80mm deep so aim for 100mm long pieces for this

project.

|

|

Square up one edge of the slabs and arrange them as pictured with

the heart facing outwards - this is what really shows off the

grain/colour of the heartwood.

If you can find a scrap of square stock the size of the internal

space ,it will make setting up and gluing easier but is not essential.

|

|

Mark where the excess on each slab can be removed and trim it off to

make clamping easier.

|

|

I only glue two opposite corners to begin with - trying to glue all

four at once requires too many clamps for such a small space.

A bit of packing tape over the square packer will stop the glue from

grabbing it.

|

|

|

Once the first corners are dry, the next two are very easy to clamp

up. I use Titebond III for my glue-ups, mainly for the working time it

gives me, but also because it is supposed to be a stronger bond.

|

|

Once

the glue dries, you have a few options for mounting the blank on the

lathe. Here I glued it on to an old jam chuck as it simply wasn't long

enough for any other method, and used a cone on the tailstock to centre

the blank. Once

the glue dries, you have a few options for mounting the blank on the

lathe. Here I glued it on to an old jam chuck as it simply wasn't long

enough for any other method, and used a cone on the tailstock to centre

the blank.

If you have the length, the easiest method is to very carefully

mount one end in the jaws of your chuck, then turn a dovetail spigot on

the other end to mount it by more securely.

|

|

|

Part B - Making the dispenser . . .

|

|

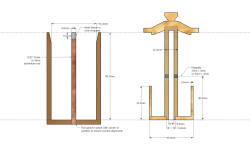

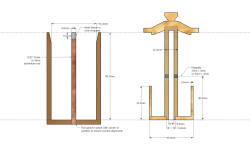

These drawings give the basic dimensions for the dispenser but I

think making a separate base looks better and helps add a little weight

to it. The key to success with this project is getting the weight of

each

component just right so it operates the way it is supposed to.

The main idea was for the dispenser to be one-handed in use - no

need to pick the dispenser up and shake aimlessly till something falls

out!  Lift the lid with one hand, grab a toothpick, then tap the lid for it to

close gently on a cushion of air. The base should stay put when you lift the lid, and once

the carrier is raised enough for the magnets to attach to the centre

shaft, any further lifting should lift the base as well. This way you

would have to intentionally hold the base down to remove the carrier for

refilling etc and avoid too many unwanted spills.

Lift the lid with one hand, grab a toothpick, then tap the lid for it to

close gently on a cushion of air. The base should stay put when you lift the lid, and once

the carrier is raised enough for the magnets to attach to the centre

shaft, any further lifting should lift the base as well. This way you

would have to intentionally hold the base down to remove the carrier for

refilling etc and avoid too many unwanted spills.

|

|

With the blank securely mounted on the lathe, square off the end and

drill/turn the inside to just over 40mm diameter.

|

|

Turn the cylinder down to leave a wall of 3 to 4mm. Fill any voids

at this point, particularly on the upper half of the inside if there are

any - if the toothpicks lodge in a hole there they will jam and stop the

dispenser from opening properly. (Don't ask me how I know this!)

|

|

A length of dowel (broom handle!) with a slot sawn in one end

makes a brilliant sander for the insides of the cylinder, particularly

if you're using Abranet.

|

|

Don't forget to taper the inside edge a little to let the toothpicks

lay out further, then sand and finish before parting the cylinder off

(and catching it of course!)

|

|

With the cylinder complete, all other parts can be tuned to fit it's

dimensions if it didn't quite go to plan.

|

|

A shallow recess in the base to fit the cylinder helps line

everything up and don't forget to drill a hole to suit your centre

shafts diameter

A shallow recess in the base to fit the cylinder helps line

everything up and don't forget to drill a hole to suit your centre

shafts diameter . .

Sand, finish and part the base off your blank. You can

of course make the cylinder and base from one piece if you like and

ignore some of these steps.

|

|

Turn the lid next - it does NOT need to be a snap-fit - a little

loose is good on this project to ensure it drops fully home. The lighter

the lid is the better, so try and turn it as thin as practical.

|

|

Sand and finish the underside and lip of the lid, then drill the

12mm hole to take the carrier post.

You can include a knob/finial if you're happy for it to use the same

timber, then part the lid off the blank..

|

|

If

you're making a separate knob for it, reverse the lid in the chuck,

gently to avoid denting the lip, and finish the top side. Drill a hole

to suit your choice of knob/finial. I used a 5mm hole on this one to

take a hand shaped knob I will make later. If

you're making a separate knob for it, reverse the lid in the chuck,

gently to avoid denting the lip, and finish the top side. Drill a hole

to suit your choice of knob/finial. I used a 5mm hole on this one to

take a hand shaped knob I will make later.

|

|

So far so good! . Now for the internals.

|

|

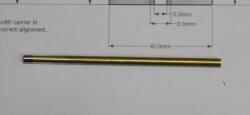

Now is a good time to get your centre shaft ready. You can use any

non-magnetic material for this part - wood, plastic, aluminium, doesn't

matter, as long as it stays straight and you can attach a small piece of steel/iron to

the end of it. I used 3/16" brass rod on this one and turned a small

step on the end which I slipped a steel sleeve over. In the past, I

have just turned the diameter down on the end to suit the thickness of

some garden tie-wire and wrapped that around it with a dob of CA to make

sure it stayed put - worked fine!

as it stays straight and you can attach a small piece of steel/iron to

the end of it. I used 3/16" brass rod on this one and turned a small

step on the end which I slipped a steel sleeve over. In the past, I

have just turned the diameter down on the end to suit the thickness of

some garden tie-wire and wrapped that around it with a dob of CA to make

sure it stayed put - worked fine!

|

|

A light-weight timber is best for the cup and connecting tube - the

lighter it is, the less magnet-power you need later.

A light-weight timber is best for the cup and connecting tube - the

lighter it is, the less magnet-power you need later.

Turn the outside down to about 1mm less than the internal diameter

of your cylinder - it should slide easily through the length of the

cylinder.

|

|

Drill/turn the inside of the cup to leave about a 2mm wall and 3 or 4mm thick base.

Drill an 8mm hole through the base then part the cup off.

|

|

Drill your connecting tube blank (which should be a couple of mm

over length) right through with a drill just a bit larger then the rod

you're using for the centre shaft BEFORE you turn the outside.

A longer than standard drill bit is the best bet here. You can try

drilling in from each end with a standard bit but if the finished hole

isn't dead straight, the dispenser is not going to work very well. The

long bit is very likely to wander off course, but as pictured here, you

can still use the blank as long as the thinnest side is still greater

than 3mm.

A longer than standard drill bit is the best bet here. You can try

drilling in from each end with a standard bit but if the finished hole

isn't dead straight, the dispenser is not going to work very well. The

long bit is very likely to wander off course, but as pictured here, you

can still use the blank as long as the thinnest side is still greater

than 3mm.

|

|

Now you can turn the outside down to size with the blank mounted

between the ends of the hole to ensure everything is true to the hole.

Turn the step on one end to 8mm to suit the cup and test it for fit -

any excess can be trimmed off later.

|

|

Drill 2 holes at right angles to each other(measured up from the

cup-end) to suit your magnets diameter.

I started out using 3mm magnets opposite each other, but changed on

this dispenser to 5mm magnets at right-angles and found they will still

fit in the connecting tube OK but get a far better grip on the shaft.

|

|

To hold the magnets in place, I slip the tube over a steel rod and

position the magnet so it touches the rod, then put just a drop of CA on

the magnet which holds it nicely.

|

|

Forgot to take a pic of the next step. Sit everything together and

the lid should be sitting up above the cylinder by a couple of mm.

Measure the gap from the top of the cylinder and the lid, then cut that

distance plus 1mm of the connecting tube - this will keep the cup from

hitting the bottom of the dispenser. If everything seems to fit OK, glue

the bits together, taking care not to get excess glue down the connecting

tube.

|

|

For this dispenser I finally found a use for that old 4-jaw chuck

I've had for about 12 years and never used!!! No such thing as waste

timber - managed to get a passable knob from this other wise useless

piece of Australian Ebony.

|

|

And we're done!

Please use the Feedback form for

any questions or comments on this project.

|

|

The Evolution of an idea.

From left to right . . . From left to right . . .

1. Prototype made from a solid blank of

Zig-zag Wattle - worked well but the

base was a bit light and tends to lift with the carrier.

2. Used a Gidgee base for more weight but messed it up by using

Gidgee for the cup as well - way too heavy so it took 4 magnets to just

barely hold the carrier up.

3. Our daily user -

Hopbush cylinder with

Red Olive Plum lid

and base - got the balance just right in this one.

4. Purple Bush-pea cylinder with Norfolk Island Hibiscus base and

lid - one for the gallery.

|

|

|