Making an Egg-chuck... |

To finish the parted end of the first couple of eggs I made, I just sanded

and hand finished to remove the stub but I decided this wasn't good enough

as I wanted fully polished eggs with no sign of how they were produced. A

few simple modifications to a PVC pipe fitting produced a simple chuck to

hold the eggs which are loosely sized on a standard XL chooks egg.

A friend asked me to make them a chuck so here is the step-by-step ....

|

Start with 1.5" PVC pipe coupling.

|

Mount it on your standard chuck jaws centring it as best you can.

|

|

Use a parting tool to separate the tube past the end of the thread by 15 or 20mm.

|

|

Use a skew chisel to cut a notch to suit the dovetails of your chucks jaws.

|

Reverse the tube onto the jaws and true up the end and inner diameters with a scraper styled tool.

|

|

Screw the outer ring on and true up the inner diameters with some form of scraper - I use a Sorby hollower for this type of cut.

|

|

Cut 2 disks of scrap timber just bigger than the largest inner diameter of the PVC fittings. I use ply for strength in all directions

but any scrap will do. Drill the centre of the disk and mount it on a

screw-chuck with a scrap timber spacer behind it to keep your tools away

from the chuck.

|

|

Shape the disk to fit snugly inside the base of your egg-chuck. If you

take too much off, a layer of masking tape will take up the slack - it's

not that crucial but you do want it tight enough to stay in place while

the seat for the egg is cut.

|

Mount the egg-chuck base on the jaws and fit the disk in place. Turn a bowl shaped recess into it to suit the shape

of the big end of the eggs you create.

|

|

Mount the 2nd disk on the screw chuck the same way and shape it to fit snugly......

|

|

.... inside the outer ring.

|

|

Remove the disk from the screw chuck and grip it in your standard jaws but do not tighten it too much

as you will be left with a fairly thin ring which will crush easily. Turn

away enough material working from the centre outwards to allow the small end of

an egg to protrude far enough to work on finishing it. Be careful doing this as you are working very close to the steel jaws.

|

|

You may need to 'tune' the seats in the disks to get the 2 disks close enough to each other

to allow the outer ring to screw on to the base sufficiently. (I would want at least 2 full turns connected)

|

|

There ya go Toni!

|

|

| Back to Top |

|

The Eggsactly gauge... |

|

|

After turning about 30 or 40 eggs with no end in sight to the types of timber

available, I thought it might be a good idea to have a gauge to help make

sure the eggs would fit in the egg-chuck OK.

The gauge is about as simple as they get and could be made from just about any material you have on hand - mine is just a scrap

of Lamipanel (Nope! No hole in the bathroom wall!) The 'caliper' side is about 44mm and the 'length' marker is about 56mm.

The gauge is about as simple as they get and could be made from just about any material you have on hand - mine is just a scrap

of Lamipanel (Nope! No hole in the bathroom wall!) The 'caliper' side is about 44mm and the 'length' marker is about 56mm.

|

|

| Back to Top |

|

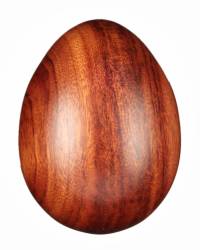

Photographing the eggs... |

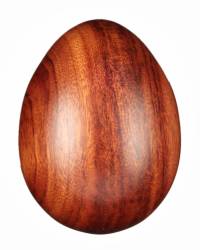

This is not so much a "How to" as it is a "How do I" photograph the

eggs as I'm still not 100% happy with the results I'm getting with my

current setup but I don't know what else I can do to improve them any

further. If you have any tips or ideas, please leave me a note using the

'Feedback' page. The photos from egg #462

onwards are about as good as I can get them - except the reflection from

the 2 halogen lamps - if I could get rid of that I'd be a very happy

camper!

|

This is the setup I have used for the eggs from #462 onwards. The

stand was ratted from an old transparency projector and the tent-frame

is just some aluminium angle glued together. The tent was made to

completely surround the frame but I found that all that whiteness

reflecting off the eggs was part of my problem - now I'm only using it

to diffuse the 2 x 150W halogen lamps a little.

This is the setup I have used for the eggs from #462 onwards. The

stand was ratted from an old transparency projector and the tent-frame

is just some aluminium angle glued together. The tent was made to

completely surround the frame but I found that all that whiteness

reflecting off the eggs was part of my problem - now I'm only using it

to diffuse the 2 x 150W halogen lamps a little.

|

The background is black velvet and black cardboard was used to make

the 'ring' - all this was to avoid the white reflections or 'flare' on

the margins of the egg that have plagued me for so long. With the black

background I could finally get a crisp edge on the egg but needed a

narrow white border to make later editing possible, hence the white egg

shaped disk behind the egg, close enough that it does not reflect off

the egg.

|

The white balance is established by taking a shot of white paper

where the egg sits, the focus set to about 1/4 of the depth of the egg (eg:

halfway between the nearest point and the edge) and the aperture is set to 32

for maximum depth of field. Then I just keep swapping eggs and taking

shots using the remote so I don't even touch the camera. The glossiest

eggs get a squirt of anti-reflective liquid that wipes straight off

after the shot.

The white balance is established by taking a shot of white paper

where the egg sits, the focus set to about 1/4 of the depth of the egg (eg:

halfway between the nearest point and the edge) and the aperture is set to 32

for maximum depth of field. Then I just keep swapping eggs and taking

shots using the remote so I don't even touch the camera. The glossiest

eggs get a squirt of anti-reflective liquid that wipes straight off

after the shot.

|

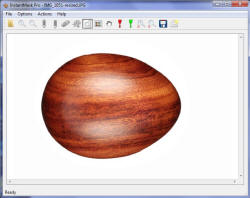

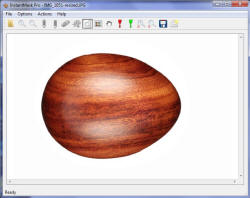

The colour reproduction from my new camera is spot-on so once the

shots are taken, all I have to do these days is remove the background, crop and resize.

|

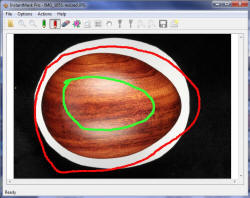

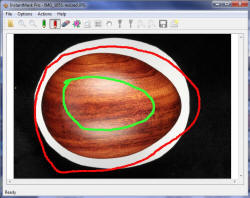

I use a program called 'Instantmask Pro' to very easily remove the

background - you just scribble a line on the egg with the green pen,

scribble a line on the background with the red pen and hit the preview

button - magically simple!

I use a program called 'Instantmask Pro' to very easily remove the

background - you just scribble a line on the egg with the green pen,

scribble a line on the background with the red pen and hit the preview

button - magically simple!

|

I then use Zoner Photo studio to crop a 4:5 ratio section out with

the egg and resize it to 200 x 250 pixels - all done!

This process beats the hell out of how I used to get these pics but

I would still love to get rid of those reflections from the lights so

any suggestions would be appreciated.

|

|

| Back to Top |

|

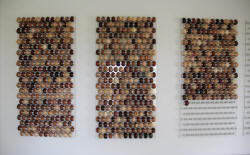

Collectors/Display Cabinet... |

|

|

A pile of egg-cartons stretched across the couch in the living room

is not the most attractive way to show off a collection of anything so I

designed and built this cabinet to suit my needs.

In 'collectors' mode, it is a simple 4 drawer cabinet standing about 1400mm high made from Rose Mahogany (dysoxalum fraseranum).

The cabinet can be lifted off the stand to make transporting the unit to

shows and craft fairs easier and the stand sports another 'utility'

drawer.

In 'collectors' mode, it is a simple 4 drawer cabinet standing about 1400mm high made from Rose Mahogany (dysoxalum fraseranum).

The cabinet can be lifted off the stand to make transporting the unit to

shows and craft fairs easier and the stand sports another 'utility'

drawer.

|

In 'display' mode, the top is lifted off and the drawers

removed and stood on their faces around the cabinet. The top is then

placed back on to lock it all together. The whole top section sits on a

bearing allowing it to rotate like a jewellery case and can be lifted

off the stand to be used independently on a table or bench if required.

Sounds easy but with over 200 eggs in there it's a lot heavier than it

looks!

One of the criteria in my design was to include expandability and

the idea was that another set of drawers could be added on top. While

this idea still holds true, I will be making a stronger stand for it,

possibly containing another 8 drawers, to cope with the weight of so

many wooden eggs.

To see a 'how to' on the making of the cabinet, follow this link to

the

Ubeaut Woodworkers Forum that I spend way too much time on!!!

|

|

| Back to Top |

|

Gallery Egg display boards... |

|

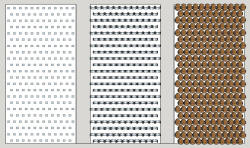

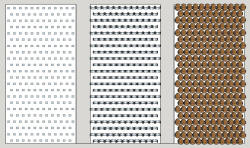

Ever since I filled the cabinet I realised I needed an expandable system to show

the eggs in as I couldn't even see the entire collection myself! Got to the

point where I was making the eggs, photographing them, then dropping them

into egg-cartons stored in boxes in the garage - unsatisfactory by any

standards! Several years and 456 eggs later, an idea sprung to mind while

trying to get to sleep one night and a couple of months later I was grinning

from ear to ear when I finally finished these and hung them on the wall in

the gallery.

Ever since I filled the cabinet I realised I needed an expandable system to show

the eggs in as I couldn't even see the entire collection myself! Got to the

point where I was making the eggs, photographing them, then dropping them

into egg-cartons stored in boxes in the garage - unsatisfactory by any

standards! Several years and 456 eggs later, an idea sprung to mind while

trying to get to sleep one night and a couple of months later I was grinning

from ear to ear when I finally finished these and hung them on the wall in

the gallery.

|

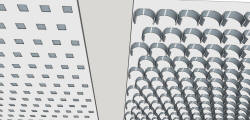

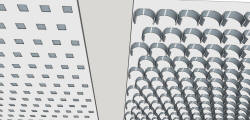

Started out with some experimentation making the clips from PVC pipe and gluing it to Perspex

until I was satisfied the idea could work. Next I drew the plan up using

Sketchup to work out the best layout and to get some idea of how the

finished product might

look.

Started out with some experimentation making the clips from PVC pipe and gluing it to Perspex

until I was satisfied the idea could work. Next I drew the plan up using

Sketchup to work out the best layout and to get some idea of how the

finished product might

look.

I decided to aim for 1000 eggs in total as I probably won't live long

enough to pass that figure and won't have to worry about building more

boards. With the layout I chose it fits 253 eggs per board for a total of

1012 eggs.

|

|

Grabbed

a sheet of 10mm Perspex and cut it into four equal pieces and then got a

good friend with a big CNC to cut the 'flutes' into it according to the

Sketchup drawing, plus some 'keyhole' slots to hang the boards from. The

main purpose of the flutes is to increase the gluing area but they also

served as precise locators for the clips and kept the eggs closer to the

board. I also polished the edges of the boards before removing the

protective paper to complete the 'transparent' look. Grabbed

a sheet of 10mm Perspex and cut it into four equal pieces and then got a

good friend with a big CNC to cut the 'flutes' into it according to the

Sketchup drawing, plus some 'keyhole' slots to hang the boards from. The

main purpose of the flutes is to increase the gluing area but they also

served as precise locators for the clips and kept the eggs closer to the

board. I also polished the edges of the boards before removing the

protective paper to complete the 'transparent' look.

|

|

I cut a strip lengthwise about 25mm wide out of several lengths of 40mm PVC drainage pipe

and then started cutting it into 17mm lengths on the tablesaw - slid each

length over a turned piece of waste timber for support while cutting. Didn't

count them, just calculated roughly how much pipe I would have to cut up to

produce about 1100 pieces.

I cut a strip lengthwise about 25mm wide out of several lengths of 40mm PVC drainage pipe

and then started cutting it into 17mm lengths on the tablesaw - slid each

length over a turned piece of waste timber for support while cutting. Didn't

count them, just calculated roughly how much pipe I would have to cut up to

produce about 1100 pieces.

This was followed by rounding the corners of each clip - the only method I

could find that didn't leave 'furry' overhang was taking the corners off on

the CBN wheel on the grinder - quite a few hours spent making PVC dust on

that part!

Finally the ends were 'crimped' which is the key to securely holding the

eggs in place. To get this done I made a small 'former' which I mounted in

the drill press - worked well until my shoulder got sore so I attached a

foot pedal arrangement to the press and flew through the rest.

|

The clips are glued in place with clear PVC cement. While it might not be

intended for Perspex, it does a pretty good job with enough surface area

involved in the bond. It stands the test of time OK too - I used it to make

a letter box from PVC and Perspex about 16 years ago and it is still intact!

I made the pictured wooden jigs to align the opening of each clip correctly and apply a bit of pressure

with a solid steel billet while

the PVC cement did it's thing. Having two of the jigs was essential so

that I could glue one clip in place and apply the weight, then glue the next

clip in place and transfer the weight to it, and so on. . . . . . 1012 times!!!!!

- I wasn't cut out for repetitive jobs!

|

A completed board. Would have been nice to have transparent clips as

well but I am yet to see a flexible clear plastic that doesn't go brittle

and crack in a short space of time. I don't know how long the PVC will stay

'springy' either but it will never be exposed to direct sunlight so it

should see me out at least!

|

|

All four boards loaded and hung in the gallery (which is still being fitted

out at the time of writing). Every tenth clip has a number on one side so I

don't have to look for the number on the bottom of each egg to find a

specific egg.

All four boards loaded and hung in the gallery (which is still being fitted

out at the time of writing). Every tenth clip has a number on one side so I

don't have to look for the number on the bottom of each egg to find a

specific egg.

If ever you're travelling through Emerald and you'd like to see the

collection/gallery, just drop me a line via the

Feedback page and we can make arrangements.

|

|

|

| Back to Top |

|